Headed by Waste Services Co-ordinator John Kirkhope, there is clearly a focus on preparing the Materials Recovery Facility (MRF) in Bonnybridge, Falkirk for the future, investing in state of the art technology which will help clean up and separate all the different materials arriving at site, so they can be passed onto reprocessors to turn back into new products. Any income generated from the materials will help offset the investment made in the specialised equipment.

The MRF is taking in around 50 tonnes of Co-mingled Dry Recyclables (CDR) per day from the Council’s kerbside recycling collection. The challenge is to sort this mixed stream of material into commodities for resale and remove any contamination i.e. material that shouldn’t have been placed in the collection. The commodities within the CDR are namely ferrous and non-ferrous metals, mixed plastics, cardboard and paper, all of which need to be separated out. An important task during separation is the identifcation and removal of any contamination which can affect the quality of the fnal separated product.

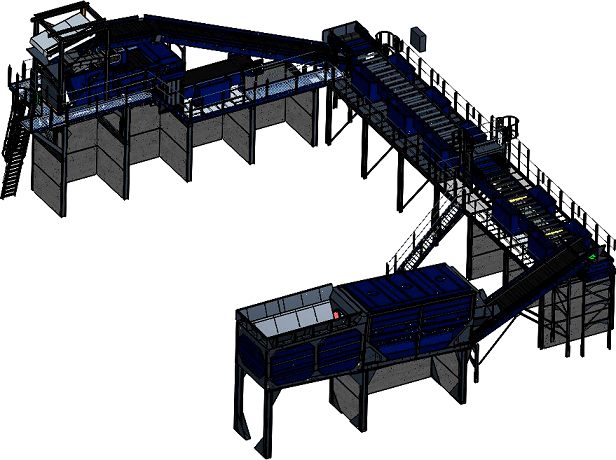

After going through a competitive tender process Falkirk Council have invested signifcantly on new equipment to sort the CDR material. The main part of this investment was made in a BlueMAC recycling facility, purchased through Blue Scotland and incorporating a 6 bay twin side picking line, over-band magnet and eddy current separators, as well as a number of conveyors to move the material.

The CDR is deposited at the MRF, Monday to Friday by a fleet of Refuse Collection Vehicles (RCV’s) and is stockpiled for processing throughout the day. The processing capability of the plant is adjusted accordingly to maximise the quality

of the fnal product allowing the team to process everything which comes in and also allowing for general cleaning of the equipment as required.